About NewFuels

“NewFuels” RSEZ SIA is the largest

producer of wood pellets

in Latvia.

2019

“NewFuels” RSEZ SIA was awarded the title of “Enterprise of the Year”.

77

people are working

at “NewFuels” RSEZ SIA

2010

“NewFuels” RSEZ SIA has been operating since 2010.

The biggest biomass cogeneration station in Latgale

The cogeneration station produces electricity and heat using renewable local resources and biomass (chips, shavings and wood bark).

3,1 MWt

Electric power of the station

10,7 MWt

Heat capacity

12,5 million €

This investment is currently one of the largest investments made in Latgale region.

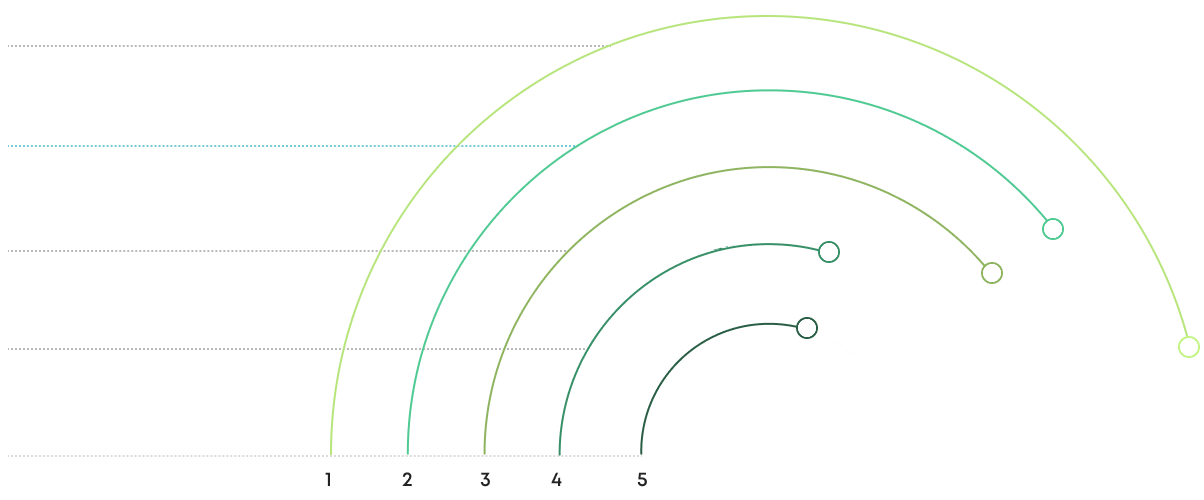

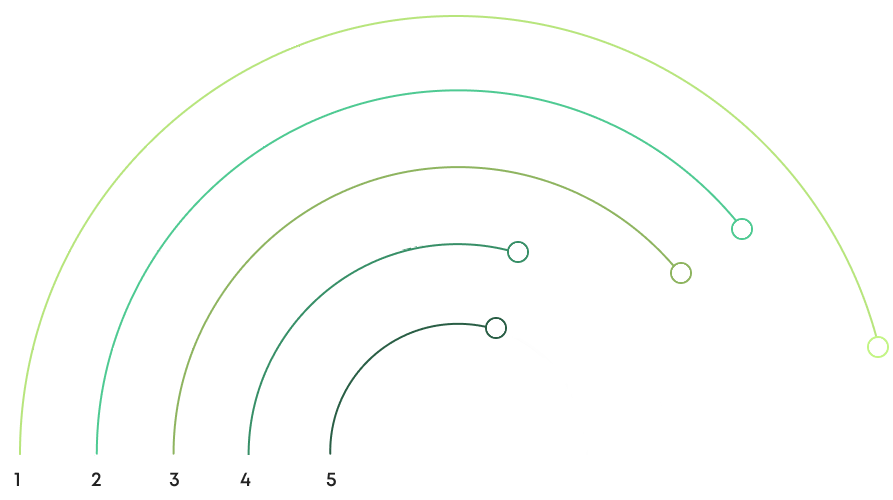

Advantages

of wood pellets

Efficiency of various

types of fuel