In the distance of 242 km from Riga, 685 km from Moscow, and 450 km from St.Petersburg at the cross of two significant lines of communication, namely motorways and railways of Riga-Moscow and St.Petersburg-Warsaw, lies the 7th largest city of Latvia – Rezekne, where Rezekne Special Economic Zone (RSEZ) has been launched and consists of 18 commercial enterprises.

Since 2010

the pellet plant of “NewFuels” RSEZ SIA has been operating here and now has become the largest producer of wood pellets in Latvia. The pellet plant currently has a production capacity of circa 270 000 metric tons

per annum.

3 557 179 €

The Plant has been 100% financed from foreign investment, which is currently one of the largest investments made in Latgale region.

“NewFuels” RSEZ SIA

carries out its activities in accordance with the highest industry requirements and has received all necessary quality certificates – SBP (Sustainable Biomass Program), EnPlus A.

In 2015

an ambitious expansion was carried out thus doubling the plant’s capacity as well as providing the possibility for “NewFuels” RSEZ SIA to produce both industrial and household pellets.

The aim of the plant is to produce ecologically clean and economically reasonable source of energy using the forestry residues in its production.

The production equipment has been purchased from the leading international companies in their respective fields of expertise as follows:

The

chipper

CBI Magnum Force (42 tons) has been purchased from „Continental Biomass Industries, Inc.” (USA). It is powered by an electrical motor with 800 KW and has a capacity of 300m3 of chips per hour.

The flaker

«Maier»

The producer of the flaker is German company “Maier”. Total capacity of flakers provides the preparation of high quality raw material for entire production.

Belt

dryer

The supplier of almost 100 m long belt dryer is “Swiss Combi” (Switzerland). Its capacity reaches up to 14 t/h of dried material.

“Energy Resources CHP” RSEZ SIA

The heat is provided by related company “Energy Resources CHP” RSEZ SIA biomass cogeneration plant, which was launched in commercial mode on August 04, 2015

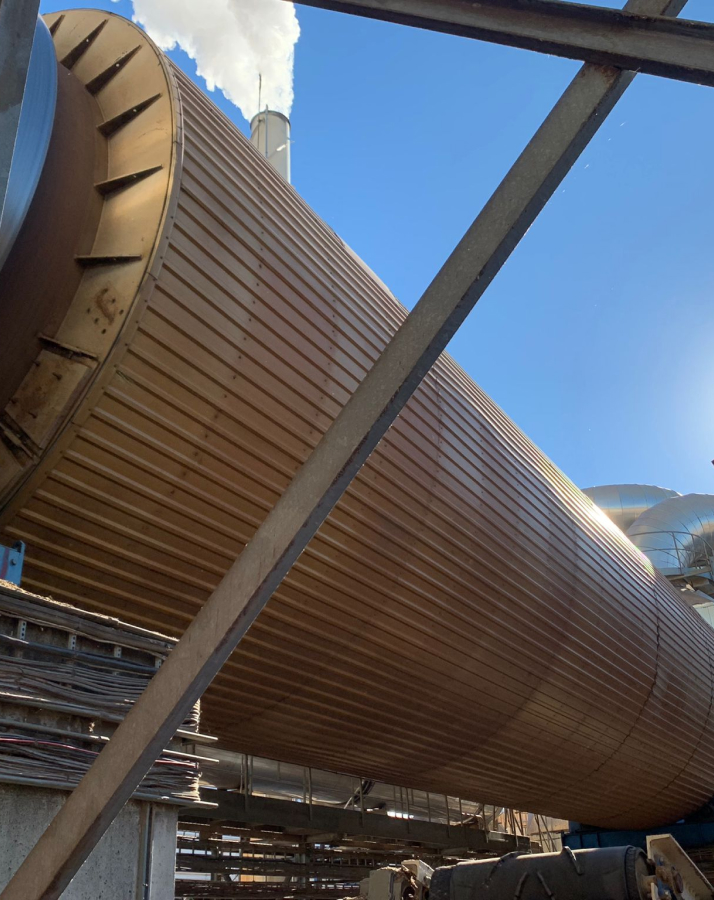

The rotary

dryer

Supplied by „Vandenbroek International” (the Netherlands) with a processing capacity of up to 17 tons of dry material per hour.

PST

conveyors

The plant currently operates with two separate lines.

Front loaders and grab handlers VOLVO and LIEBHERR are involved and truck SCANIA is used for moving the material.

Wood pellets are accumulated in silos and then transported to sea ports via railwa

Up to 33 tons of wood pellets per hour.

Is the total capacity of

the pellet plant

“NewFuels” RSEZ SIA company got the honoured 1st place in the category “Exporting Company” of Latvia in 2017 in the competition “Export and Innovation Award 2017”! Together with the main prize we also received the certificate for using the logo of the competition for the marketing purpose.

The plant corresponds with the highest fire safety requirements: the plant is equipped with the systems of FIREFLY and BUTTNER.